Ricoh UK Products Ltd (RPL) is the home of Ricoh 3D. Having harnessed over 80 years of RICOH’s manufacturing experience and a global network of employees, customers, and partners, Ricoh 3D provides a full suite of end-to-end solutions in ISO-accredited 3D printing and AM services.

-

3D Printing

-

Post-processing solutions

-

Consultancy

-

Design

-

Quality assurance

-

Commitment to Sustainability

-

Commitment to Fulfilment through Work

3D Printing

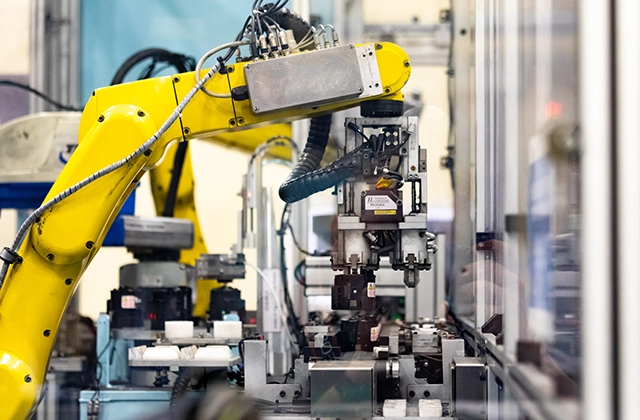

Ricoh 3D epitomises the vision of a ‘total solution’ in additive manufacturing. Our 3D printing services are designed to take products through their full development cycle, from design, to prototype, to end-use part.

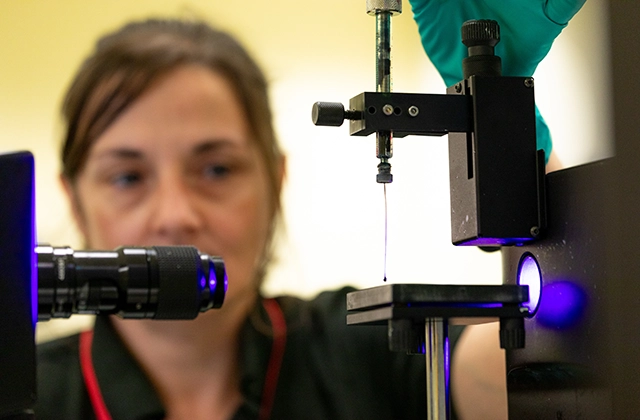

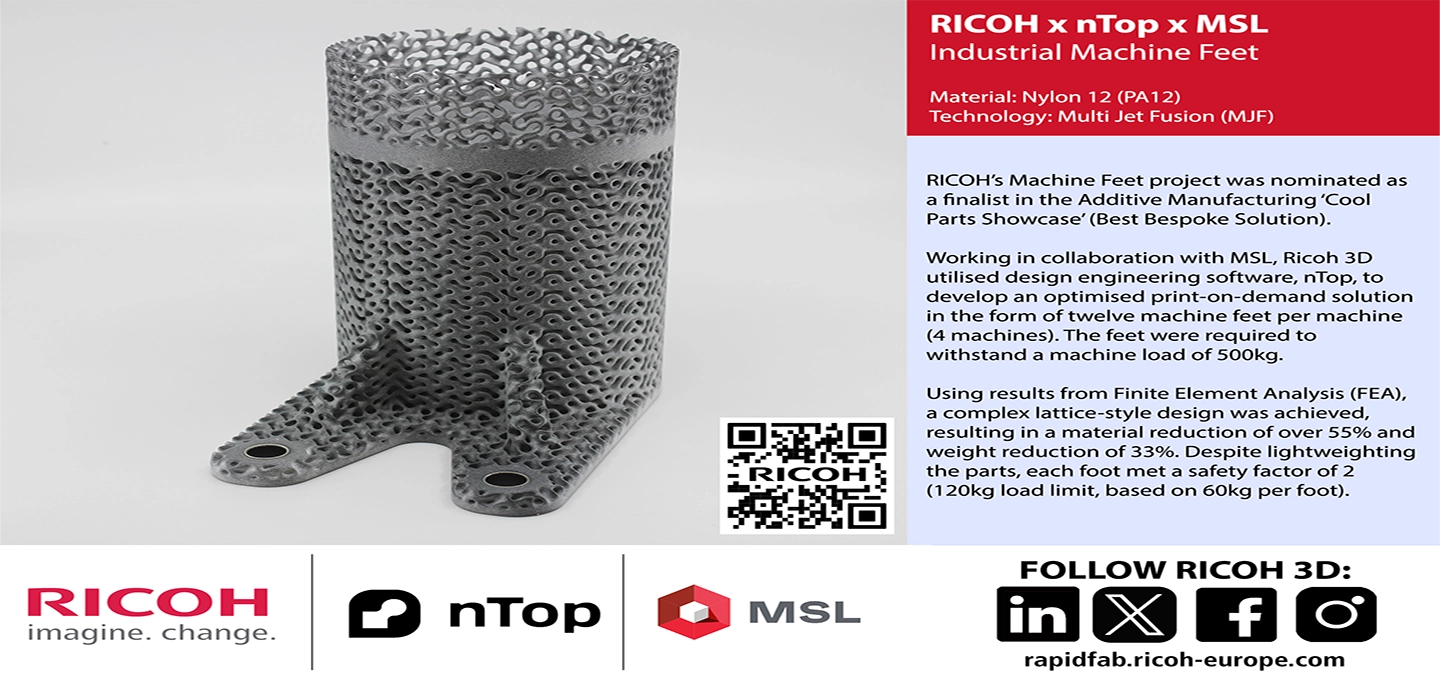

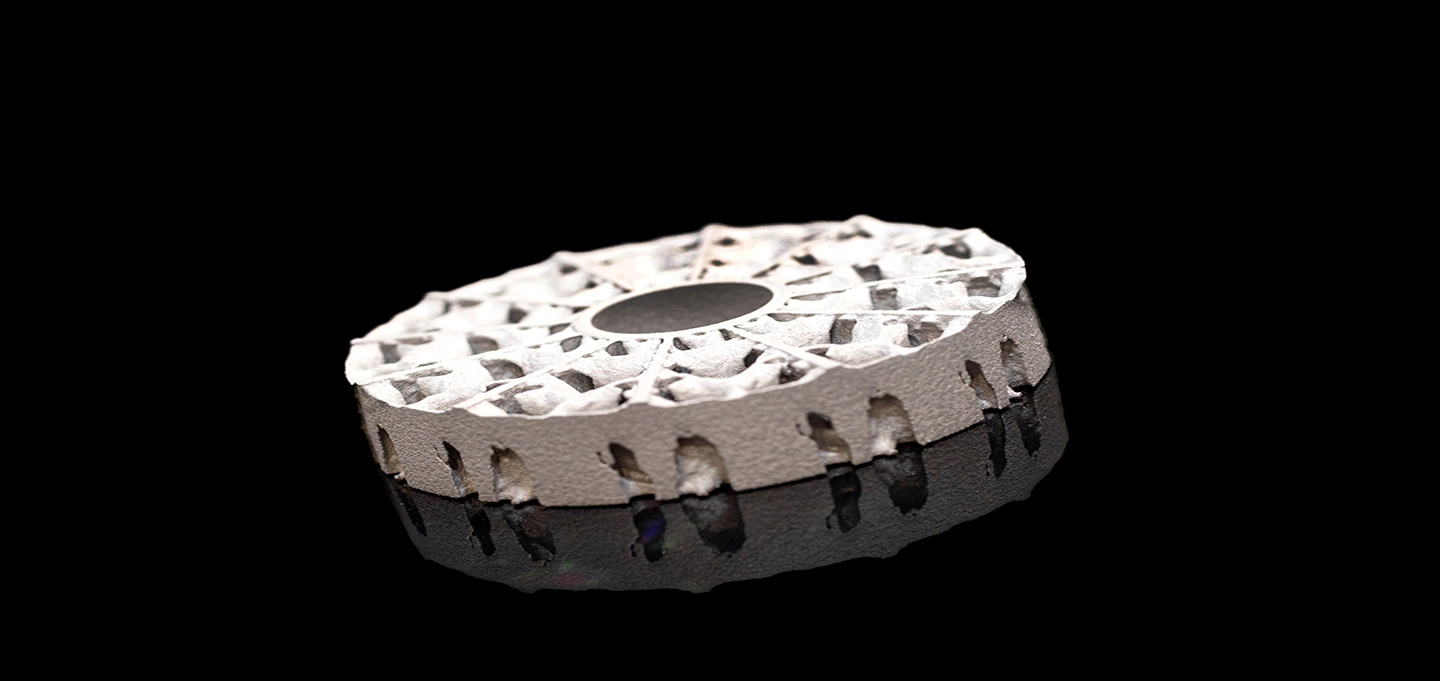

Our technical services span across various 3D printing technologies, some of which are unique to RICOH. We currently offer Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Fused Deposition Modelling (FDM), Composite-Based Additive Manufacturing (CBAM), and Aluminium Binder Jetting (BJT). Our technologies and equipment have evolved through years of Research and Development (R&D), innovation and customer co-creation activities, in addition to substantial investment in our state-of-the-art 3D printers and facilities.

We also offer a comprehensive range of engineering materials, including;

- SLS - Polypropylene and DuraForm PAx Natural

- MJF - MJF PA12

- FDM- ABS-ESD7, ABS-M30, ASA, Nylon 12, Nylon 12 CF, ULTEM 1010, ULTEM 9085

- CBAM - Carbon Fibre PEEK and Carbon Fibre PA12

- BJT - Aluminium

- As well as a large selection ofinjection moulding materials.

By understanding the properties of these, Ricoh 3D’s engineers can make appropriate recommendations to customers to achieve their desired goals. For those who prefer a ‘self-service’ approach, customers can also benefit from a ‘Material Decision Matrix’ on the Ricoh 3D website, before using an instant quotation and ordering portal.

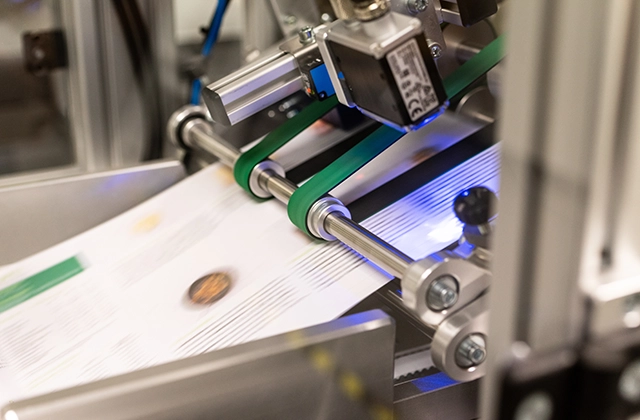

Post-processing solutions

Thanks to our 3D post-processing solutions, we can offer a wide variety of ‘finishing’ options that both enhance aesthetics of parts and advance performance. The Ricoh 3D team are equipped with the knowledge to suggest optimal finishing services according to a part’s purpose and end-use. Such examples include the following:

• Adhesion | By dividing a model, fabricating, and then bonding it together, larger products can be produced.

• Smoothing | Using an automated process, parts are chemically smoothed to improve the surface finish.

• Dyeing | Using an automated process, parts produced via SLS and MJF can be dyed.

Consultancy

Design

Quality assurance

- ISO 9001:2015 (Quality Management System)

- ISO 14001:2015 (Environmental Management System)

- (BS) OHSAS 18001:2007 (Health & Safety Management System)

- ISO / IEC 27001:2013 (Information Security Management)

- ISO 13485:2016 (The Production of Medical Devices as stipulated by the customer using 3D printing technology).

Commitment to Sustainability

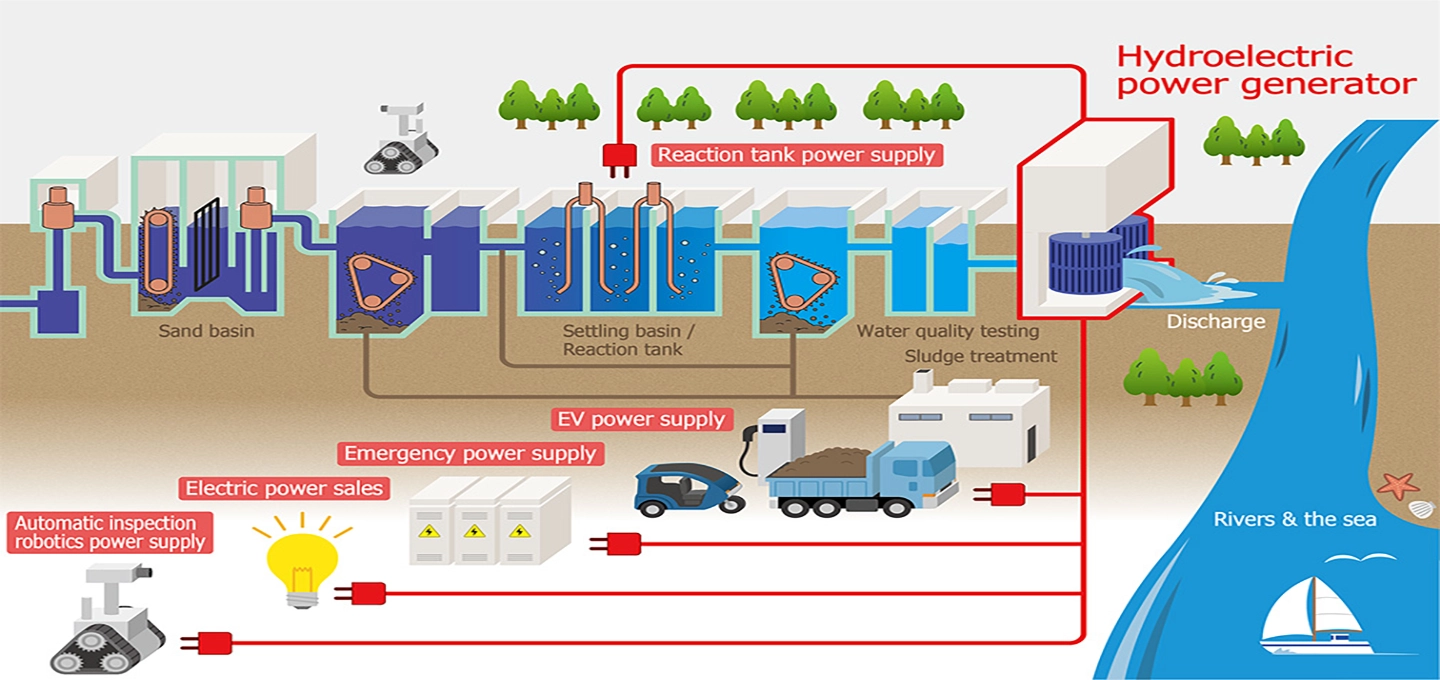

We are proud to have a vision of “Manufacturing a Sustainable Future” and we support the United Nations’ Sustainable Development Goals (SDGs) in all that we do. Irrespective of project, we consider our customers’ requirements but also how we can help them become more sustainable, for example, aligning products and services to individual SDGs. For instance, through the production of medical products, we support SDG3 – Good Health & Wellbeing. Other key SDG focusses include Industry Innovation & Infrastructure, Partnerships with Others, Climate Action, Decent Work & Economic Growth, Affordable and Clean Energy, and Responsible Production and Consumption.

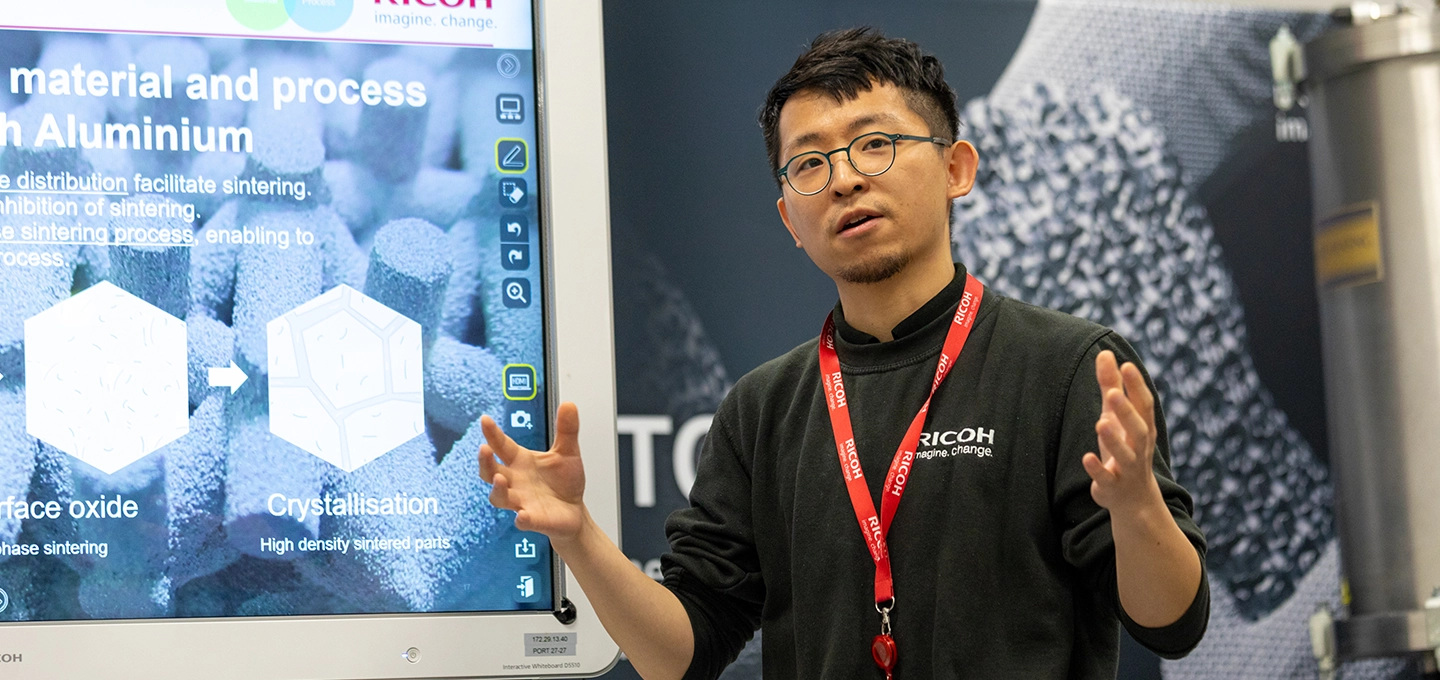

Notably, with the launch of our unique aluminium binder jetting technology, we are encouraging collaboration and co-creation activities, manufacturing applications which support the realisation of a zero-carbon society. This includes but is not limited to batteries, electric vehicle (EV) components and heatsinks, all of which contribute to a reduction in carbon emissions.

Commitment to Fulfilment through Work

Ricoh 3D enables customers’ Fulfilment through Work by providing products and services that address ‘pain points’ whilst offering wider manufacturing solutions. With a fully comprehensive offering, Ricoh 3D operates as more than a printer, but a partner too, ensuring it works to transform business processes to help organisations become more agile, productive, and profitable. Furthermore, through co-creation activities, the team empowers customers to support their own customers as well.

Internally, Ricoh 3D’s employees also find Fulfilment through Work by having the creative freedom to collaborate with customers and partners on a diverse range of projects, driving innovation in 3D printing. Together, and working closely with RICOH Futures Research and Development (R&D) team, we push the boundaries of technologies to shape the future of 3D printing. This provides a working environment of new learnings, development, and endless possibilities.