At Ricoh UK Products Ltd (RPL), RICOH’s Global Inkjet Technical Centre (IJTC) was established in 2014. This dedicated facility consists of technical and sector experts with varied backgrounds and experiences who collaborate with customers to address their printing needs. IJTC is at the forefront of inkjet innovation and development, playing a strategic role in the global inkjet industry.

-

Product & Service Offering

-

Commitment to Sustainability

-

Commitment to Fulfilment through Work

Product & Service Offering

At RPL’s Inkjet Technical Centre, we are aligned to RICOH’s industrial printing mission of being a digital solution “one stop shop”, delivering meaningful inkjet capabilities at speed and quality. Our products and services revolve around the core principles of technical support, strategic guidance, and comprehensive training to meet our customers' printing needs.

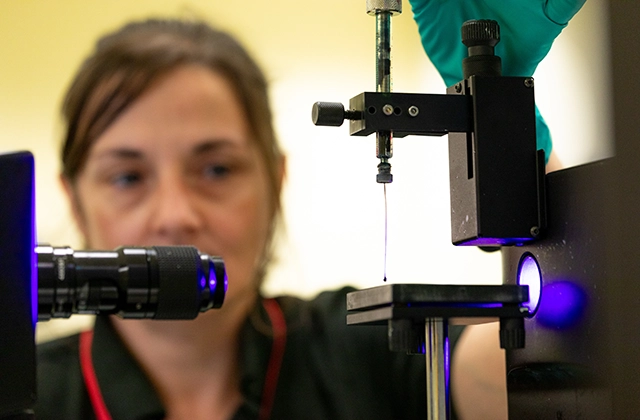

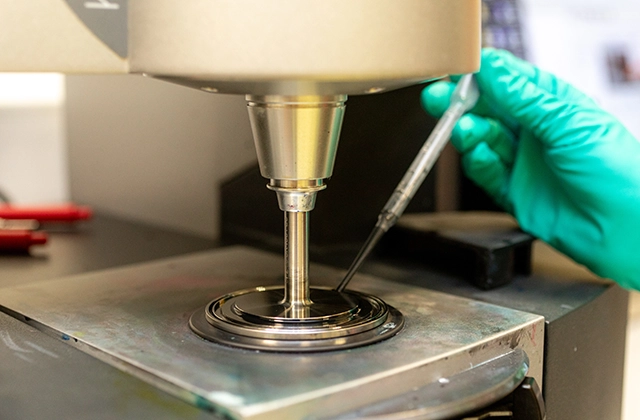

Ink Characterisation

In Inkjet we use a series of characterisation methodologies and analytical instruments, to gain a preliminary understanding of ink properties. These include surface properties, ink bulk viscosity temperature profile, particle size distribution, ink system stability, ink bulk density and speed of sound, complex rheology, ink oxygen properties and ink miscibility. Test services can be selected to investigate and compare any given ink against RICOH target specifications or criteria. This gives an indication of conditions and parameters for inkjet jetting investigation, in addition to guidance of areas to improve for ink formulators to achieve optimal printing performance.

Ink Printhead Interaction

Inkjet heads are often described as the vehicles to deliver ink to the right place with the correct quantity, quality, and precision. RICOH printheads are designed to have an extremely flexible waveform function which improves the ability to tailor the printhead delivery to suit the ink, rather than tailoring the ink to suit the printhead. We use multiple methodologies (standard, advanced, full) and in-depth testing to gain knowledge of ink and printhead ‘interaction’ on both chemical and physical levels.

Ink Printhead Substrate Interaction

Various surface treatment capabilities help to address challenges with special substrates, like corona, flame, and chemical priming. Here, there is no pre-determined test method, however, IJTC experience, expertise and knowledge in chemistry, electronics, software, and engineering are all dedicated to guide and support any customised experiments for problem solving or project development.

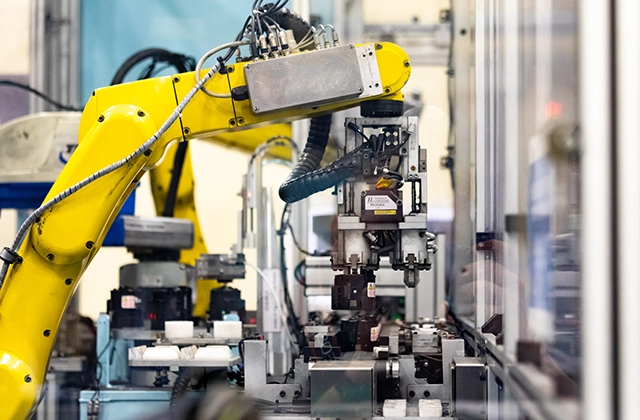

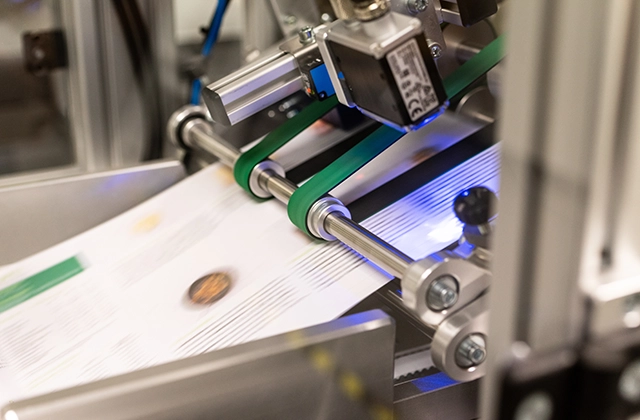

Inkjet Printing System

IJTC has access to various types of industrial RICOH printer models. Fully equipped printing lines can provide good insight into viable solutions for other applications using the same or similar technology. Multi-pass and single-pass equipment, UV and water-based systems give a visualisation of how RICOH printheads perform in a mature device.

Commitment to Sustainability

RICOH not only leads in inkjet technology but also focusses on promoting Environmental, Social and Governance (ESG) practices that support the realisation of a sustainable future, whilst aligning to the United Nations Sustainable Development Goals (SDGs). Utilising digital printing through inkjet technology results in less ink usage compared to analogue methods, with virtually no waste.

RICOH’s commitment goes beyond providing more sustainable printing solutions. Our team is also looking at solutions including inkjet consumables and printing processes, which contribute to reducing environmental impact of raw materials and energy consumption.

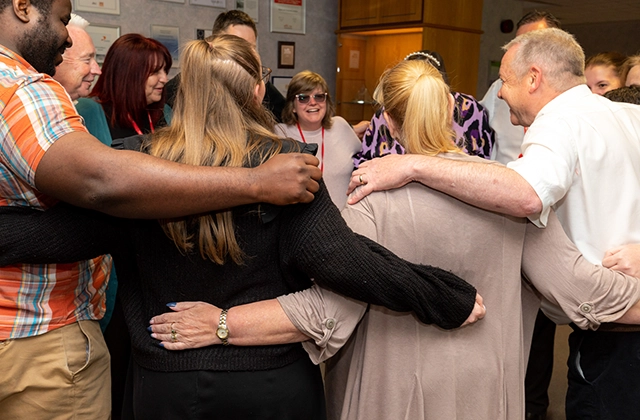

Commitment to Fulfilment through Work

The IJTC team comprises of highly qualified scientists, engineers, and technicians with a broad range of industrial expertise, complemented by access to a wide network of industry professionals. The team enables customers’ Fulfilment through Work by providing all levels of hands-on guidance and technical training to knowledge-share with customers, from the fundamentals of printhead technologies, to more complex topics such as exploring waveform design optimisation concepts. Our collaborative approach aims to facilitate seamless adaption of applications and ink, integrating RICOH printhead technology to fit the customers’ unique print requirements and providing lab support when necessary.

On the same principle, employees find Fulfilment through Work by knowledge-sharing with RICOH colleagues including Research & Development (R&D) in Japan, fostering the development of inkjet technology through teamwork. Investments in new equipment provides endless possibilities to collectively influence future designs and systems, whilst ensuring a positive and progressive workplace in which our experts can thrive.