At Ricoh UK Products Ltd (RPL), our Toner Supplies business area manufactures toner bottles 24 hours a day, 5 days a week for RICOH’s range of industry-leading hardware products, supplying the Office and Production Print sectors.

-

Product & Service Offering

-

Commitment to Sustainability

-

Commitment to Fulfilment through Work

Product & Service Offering

RICOH’s Toner Filling and Assembly area is strategically located in Telford as part of our Postponement Strategy. This innovative approach allows us to convert raw materials into finished goods using just-in-time production for maintaining customer demand whilst minimising lead times, logistics costs, and inventory levels.

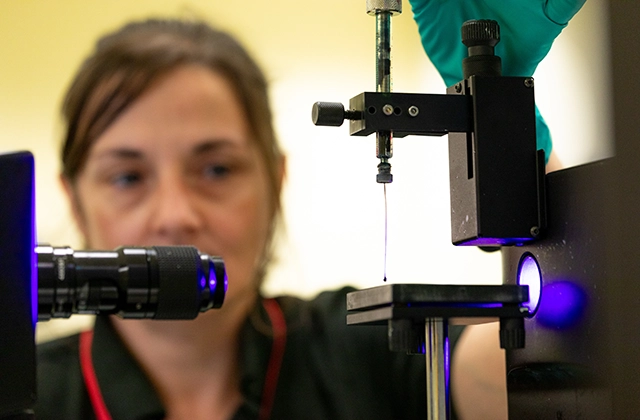

Within Toner Filling, there are five distinct manufacturing zones, including two moulding areas that utilise advanced technologies like Injection Moulding, Blow Moulding, and Injection Stretch Blow Moulding to assist in supplying the toner bottles and components to the Toner Filling area. However, working with our recycling areas, Toner filling aims to use, where possible, recycled bottles and child parts rather than creating virgin ones.

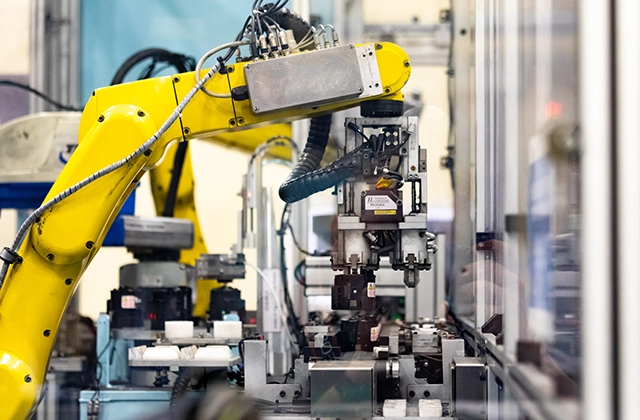

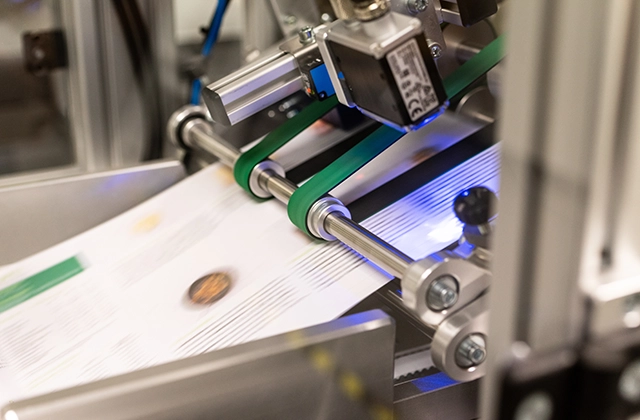

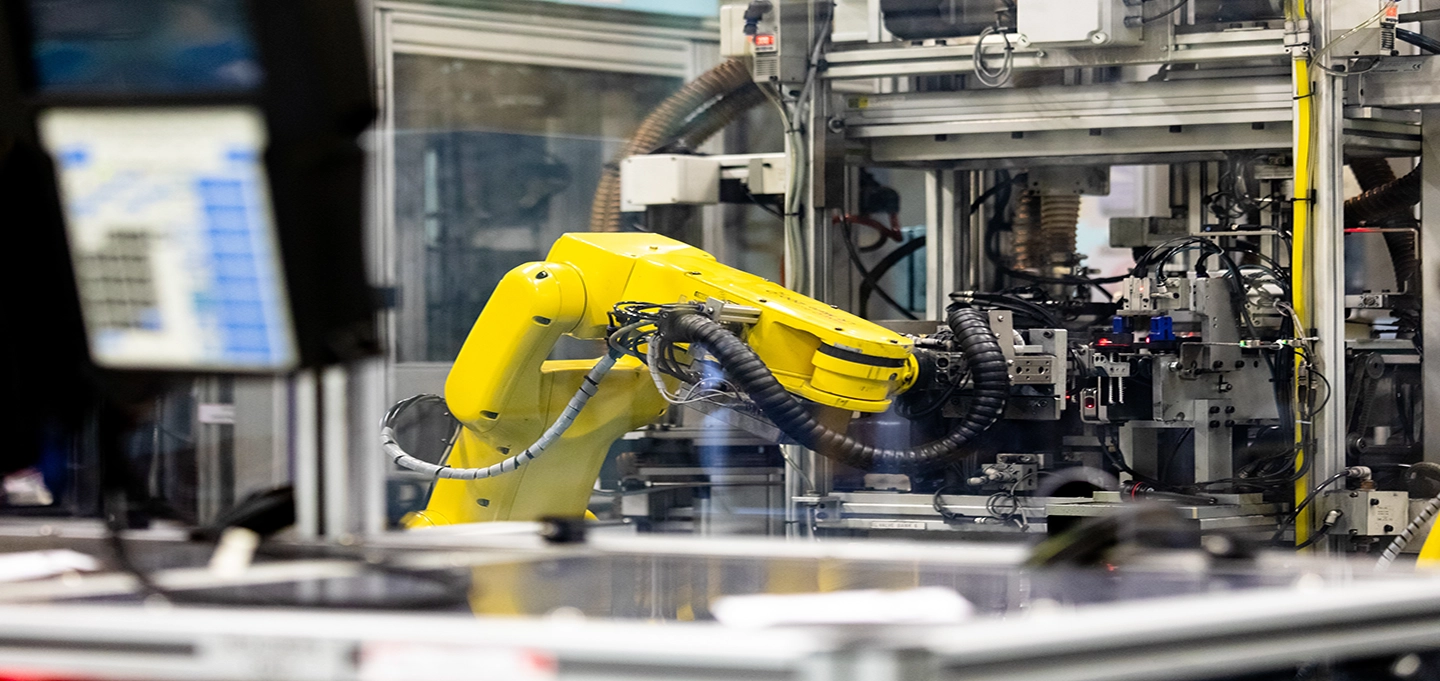

The journey of toner at RPL begins with bulk toner imported from Japan, undergoing meticulous aeration and sieving processes before being filled into product-specific toner bottles. Our automated assembly stations attach pre-assembled child parts to the bottles, monitored by robots for consistent high quality. Where necessary, the auto bagging machine packages the bottles into damp-proof bags, ultrasonically sealed for protection. The last step involves packaging the filled toner bottles for shipment to locations like BOZ (Bergen Op Zoom) in the Netherlands and some UK warehouses.

Our facility produces an impressive 194 different finished goods from various toner types, catering to diverse customer needs. The Toner Filling and Assembly area operates with efficiency and flexibility, contributing to our Just-In-Time strategy, providing in excess of 4.5 million coloured toner bottles annually to the European market - with the flexibility for larger amounts if demand required - ensuring proximity, reduced inventory, and shortened lead times.

What sets RICOH apart is our commitment to transparency. We invite customers to witness the entire operation, fostering informed decision-making. In terms of technology, our facility integrates automation and digital manufacturing to enhance efficiency, flexibility, and quality. With connectivity, real-time manufacturing telemetry analysis, and AI development, we aim to predict and alert potential process changes or failures, ensuring increased machine uptime.

Our Toner Filling and Assembly area boasts 32 high-precision robots with over 100 robotic applications handling tasks such as powder filling, assembly, packing, and moulded parts manufacture, facilitating ultra-low manufacturing costs and ensuring quality through automated inspections using the 4M methodology. From software feedback systems to robotic parts loading, vision systems, sensors, pressure gauges, and 3D barcode readers, advanced technologies are seamlessly integrated to guarantee the quality of our products. Additionally, our use of 3D barcodes supports our commitment to green policies, facilitating product return and reuse.

Commitment to Sustainability

RPL’s Toner Filling and Assembly area is deeply committed to sustainability practices. Within the factory, the focus is on energy reduction activities, showcasing responsible production. However, we are also actively promoting the use of recycled bottles and child part assemblies over virgin materials, the goal is to fill every bottle using recycled components. Aiming for a 100%-unit reuse if in good condition, this extends to various parts, including caps, shutters, holders, and bottles across the entire product range.

Leveraging digital manufacturing and automation excellence, RPL not only leads in technological innovation but also aims to reduce defect products through a system of high-quality assurance. Moreover, by manufacturing and shipping toner from locations closer to customers, RICOH significantly reduces the environmental impact associated with transportation and shortens lead times, aligning with the company's overarching commitment to sustainability.

Commitment to Fulfilment through Work

RPL’s Toner Filling and Assembly area is dedicated to enhancing customer fulfilment through a commitment to adaptability, responsiveness, and quality. We actively engage with customer suggestions and proposed process changes and our willingness to incorporate feedback ensure that customers individual needs are supported. Furthermore, our robust systems and processes enable us to provide rapid responses to market questions or issues, demonstrating our dedication to seamless customer support. By fostering a collaborative relationship and maintaining agile response mechanisms, RICOH ensures that the Toner Filling and Assembly operations contribute directly to customer fulfilment and satisfaction, characterised by excellence in product quality.

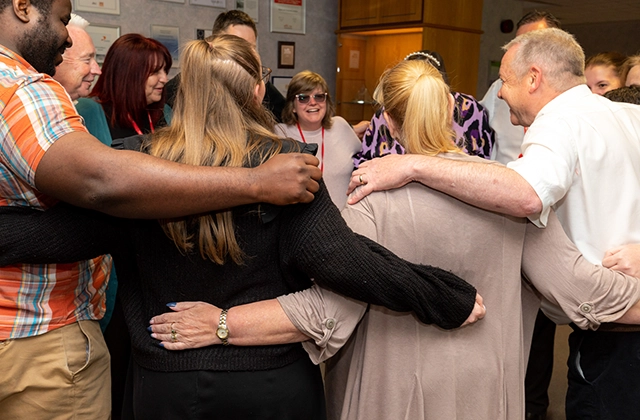

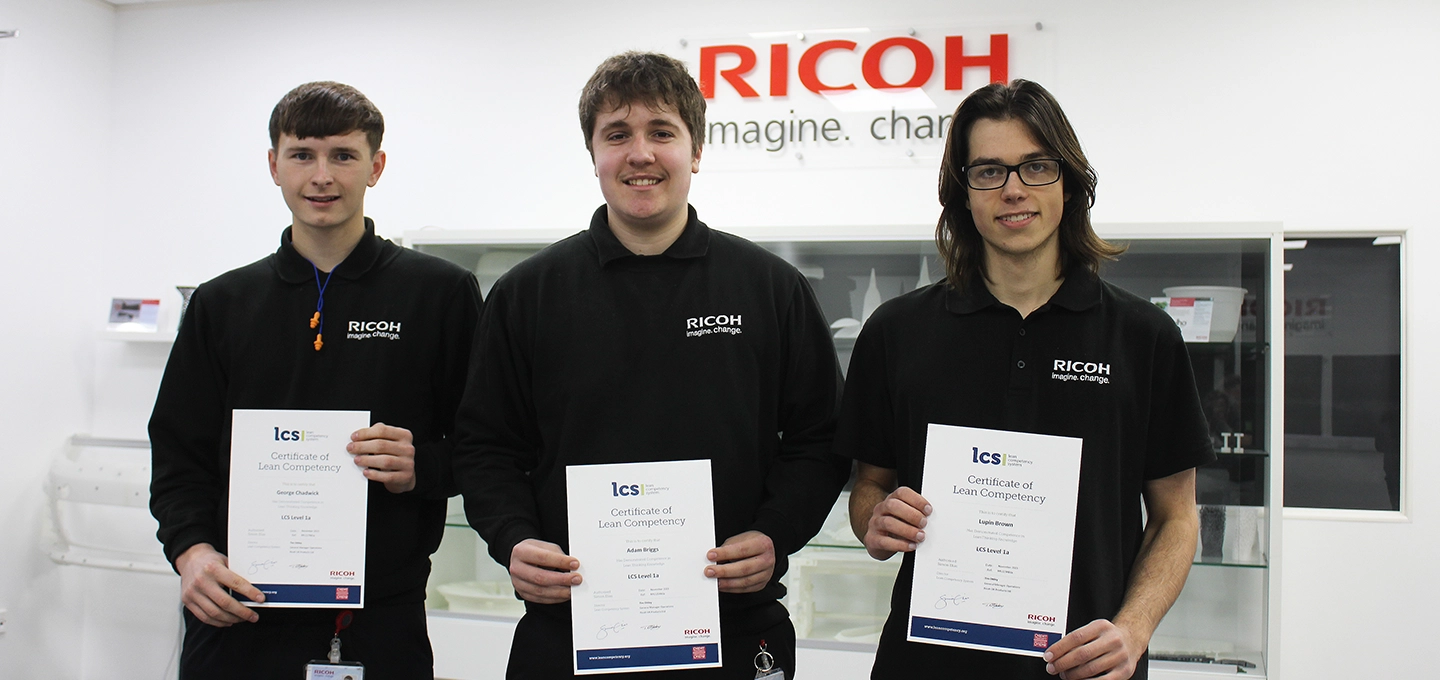

We are committed to cultivating employee fulfilment by actively engaging staff at all levels and recognising their valuable contributions. The company places a strong emphasis on employee development, offering the Cardiff University developed Lean Competency System accreditation and a dedicated development program for employees, promoting progression in their roles. RICOH fosters a culture where continuous improvement is ingrained in every employee's daily activity. To ensure employee Fulfilment through Work, RPL has established an Engagement & Recognition program comprising three core schemes: Bright Ideas, encouraging diverse suggestions for business improvement; Good Spots, promoting vigilance and prompt action to address abnormalities; and Values Recognition, facilitating peer-to-peer acknowledgment based on the RICOH Way Values.