At Ricoh UK Products Ltd (RPL), our in-house moulding facility produces a wide range of plastic components for Toner bottles which are used in RICOH’s suite of Multi-Function Printers (MFP) and Production Printers (PP). On average, our Moulding area produces an impressive 3,000,000 parts per month, showcasing our capability for high-volume manufacturing with the potential to meet further demand.

-

Product & Service Offering

-

Commitment to Sustainability

-

Commitment to Fulfilment through Work

Product & Service Offering

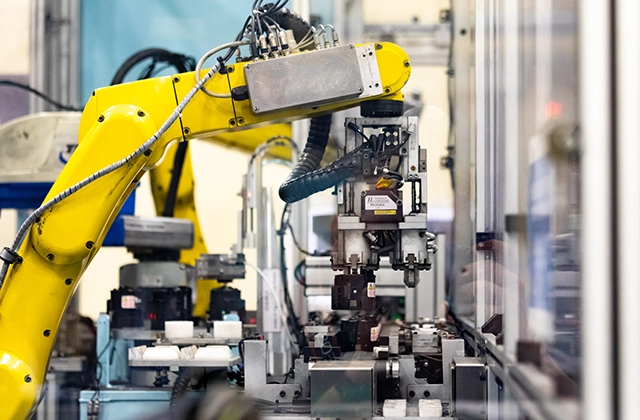

Injection Moulding

Injection Moulding is the process of “injecting” molten polymer into a mould tool that defines the shape of the moulded part. Our Injection Moulding technology consists of 13 machines, ranging from 30 tonnes to 650 tonnes of clamping pressure, with exceptional accuracy, capable of moulding technical parts down to tolerances of ± 0.03mm. This technology excels at producing repetitive detailed plastic parts for the RICOH Family Group (RFG), making it ideal for mass production.

Injection Stretch Blow Moulding (ISBM)

ISBM is a process starting with injection moulding a “preform”. The preform is transferred to a heating station before being stretched and blown into a mould tool that defines the shape of the toner bottle. RPL’s ISBM system uses post-consumer recycled Polyethylene terephthalate (PET) material with a UL94V-2 flame retardancy rating, among the most stringent in the industry. ISBM is at the forefront of producing MFP toner bottles.

Extrusion Blow Moulding

Extrusion Blow Moulding is a process where molten polymer is forced through a die to produce a hollow pipe-section called a “parison”. The parison is clamped in a hollow mould tool and sealed at one end. Air is then blown into the other end of the parison to inflate it into the shape of the mould. As part of our Extrusion Blow Moulding process, we utilise 20% of recycled material back into the process. This technology is dedicated to manufacturing PP toner bottles at RPL.

Commitment to Sustainability

Sustainability is at the core of our Moulding operations at RPL. We take pride in our utilisation of post-consumer recycled material in ISBM, the responsible use of process waste and the sourcing of virgin materials in line with RICOH’s Green Public Procurement (GPP) standard.

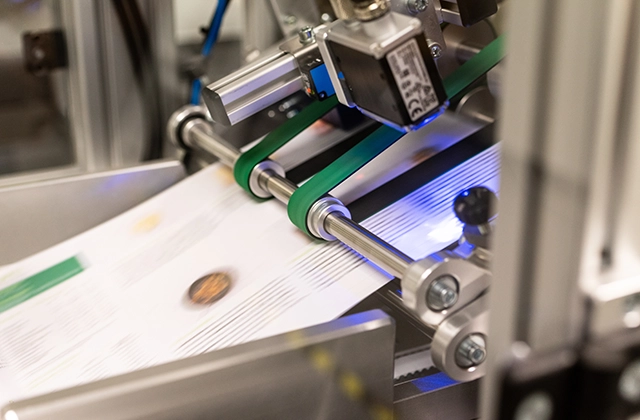

Our in-house Moulding facility means that we have a significantly reduced carbon footprint as we are not reliant on shipping raw materials, components, and end-use products from overseas. Our 100% vision inspection system assures product quality and minimises waste generation.

Our commitment extends beyond Quality Assurance (QA), process improvements and recycling, also focusing on energy reduction initiatives within the area.

Commitment to Fulfilment through Work

In Moulding, we are dedicated to employee development and industry recognition. Our setters undergo training and development programmes, gaining industry-recognised qualifications. We foster a culture of continuous improvement, utilising a cloud-based system for trend management and actively encourage our employees to suggest innovative ideas to enhance processes and ensure our products meet the highest standards.

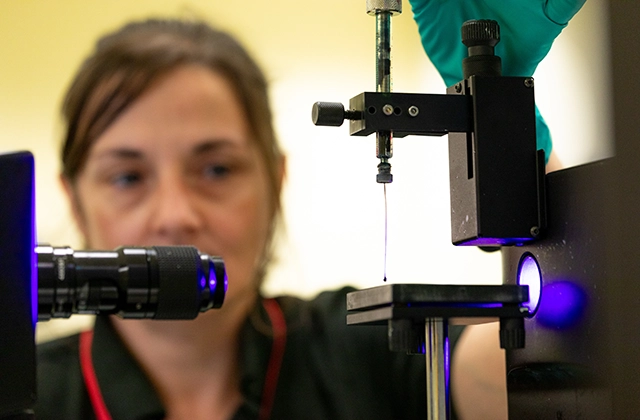

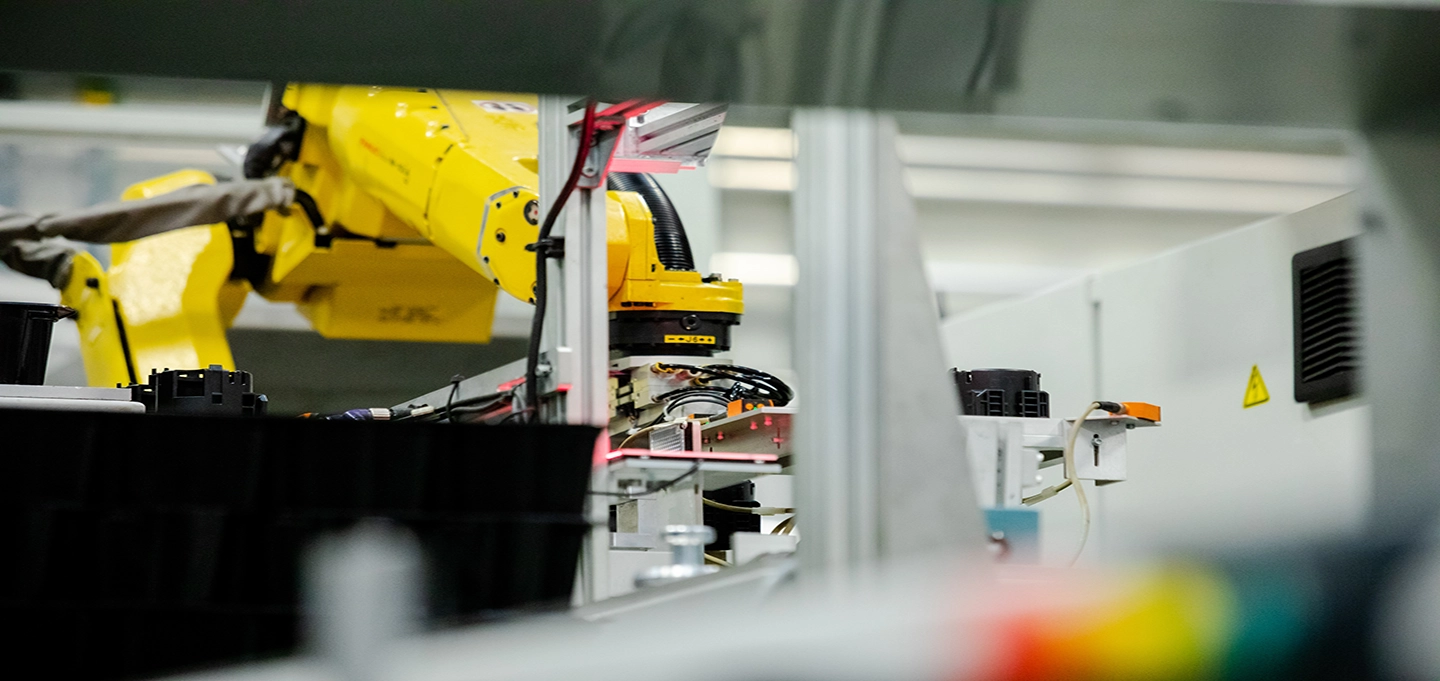

Using RPL’s digital manufacturing technical expertise, our in-house Design & Development team has implemented a 100% vision inspection system to assure quality and reduce downtime, therefore improving Overall Equipment Effectiveness (OEE) for our customers in Toner Filling – the next stage of the manufacturing cycle.

Using camera checking and laser markers with QR codes and unique serial numbers, this enables end-to-end (E2E) traceability of our products, ensuring consistent quality throughout the lifecycle of the product.