Utilising our manufacturing and technical expertise, combined with our lean and green improvement practical experience, we provide end-to-end technical solutions that maximise efficiency, profitability, and sustainability.

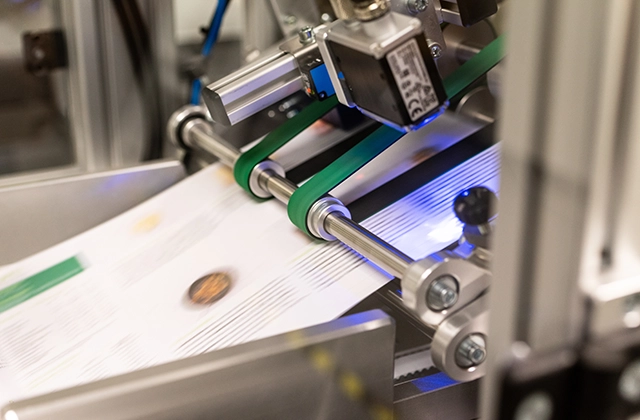

With a customer-centric approach, we partner with current and potential print customers, to remove non-value adding activities, improve workflows, automate processes, and expand “Print on Demand” capability, helping businesses thrive in a dynamic and evolving marketplace.

-

Product & Service Offering

-

Commitment to Sustainability

-

Commitment to Fulfilment through Work

Product & Service Offering

Following a three-stage approach, the RICOH team works closely with customers to DISCOVER opportunities, TRANSFORM operations, and ensure they SUSTAIN and build on their improvement. Each stage is tailored to the customers’ processes and desired outcomes.

Discover:

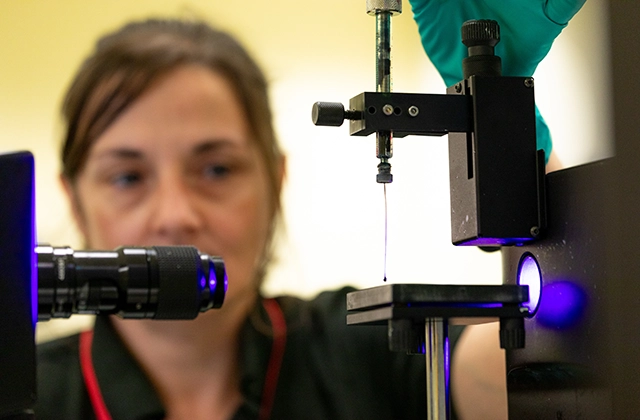

During the Discover assessment, we review the efficiency and effectiveness of customers’ manufacturing processes by conducting a Gemba tour at their facility. An initial Discover report identifies opportunities for improvement that are designed to overcome pain points. Indicative costings are subsequently provided for prioritised solutions highlighted within the report. RPL also helps calculate potential return-on-investments (ROI) and produces 2D/3D visualisation of the simulated solution where necessary.

Transform:

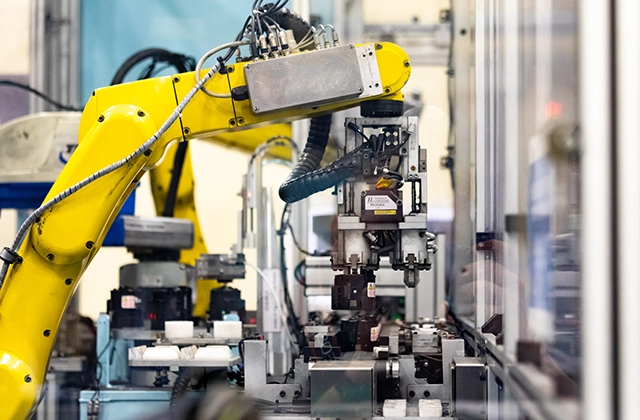

Collaborating with a robust network of partners, the RMS team Transforms operations, enabling customers to navigate evolving market dynamics and solidify their position as an industry leader. Solutions are provided such as:

• Designing and implementing assured, integrated automation solutions into end-to-end (E2E) processes, complying with UKCA, CE and ISO standards.

• Introducing new capabilities to bring “Print on Demand” solutions in-house, giving customers true flexibility for a more direct and bespoke approach.

RICOH’s solutions embed lean principles including improved workplace organisation, layout design and visual management, and elimination of process waste.

Sustain:

We pride ourselves on delivering consistent results and assured systems that meet customers’ unique requirements. Therefore, the process does not stop once the solution is implemented. The RMS team continues to partner with customers during the Sustain stage, with ongoing training, equipment maintenance and performance tracking. This inspires confidence in the Kaizen (continuous improvement) journey and helps identify further opportunities for future improvement and growth.

Commitment to Sustainability

Our expertise in efficiency improvement not only enhances business results, but also positively contributes to a sustainable future, by enabling customers to:

- Only print what is needed, through “Print on Demand” solutions.

- Reduce rework, by improving right first-time capability and eliminating lost/missing work.

- Reduce energy consumption, by optimising speed of print devices and other equipment through synchronisation of E2E processes.

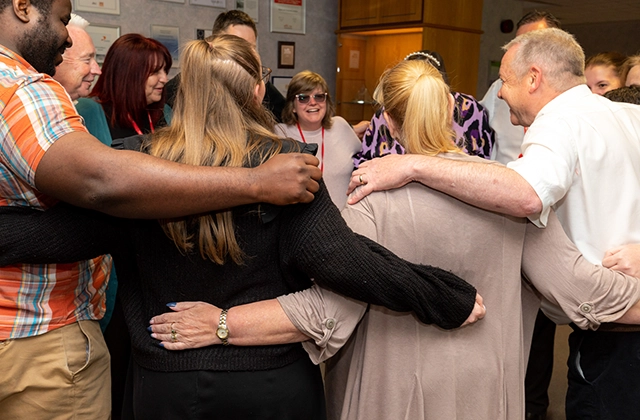

Commitment to Fulfilment through Work

With a customer-centric approach, Ricoh Manufacturing Solutions helps customers find Fulfilment through Work, by enabling their employees to work “smarter not harder”, removing process waste and tedious work, creating time to focus on value-adding activities. RMS customers have said:

“We can now save over 79 tonnes of product going to waste each year.”

“We now have over 1/3 extra capacity to grow the business without having to invest in new assets.”

“We have been able to reduce the manual work of 14 staff, enabling them to focus on more value-adding activities.”

Our own team finds Fulfilment through Work by helping customers on this improvement journey. We also personally acknowledge the importance of collaboration, innovation, and the diversity inherent in these projects, all of which contribute to digital print market growth. Our team leverages a range of skills and expertise, including practical lean manufacturing, automation engineering, design and development, toolmaking, additive manufacturing, industrial engineering, and employee engagement.