RPL supports study on micro-hydroelectric power generation in utilising 3D printers

‘Success in improving the weight of micro-hydroelectric power generation equipment, and significantly shortening the time required to create the equipment’

Earlier this year, Ricoh Company Limited (RCL) President and CEO, Akira Oyama announced that Ricoh had conducted an innovative and insightful study on micro-hydroelectric power generation in sewage facilities.

Furthermore, Oyama shared that 3D printers had been utilised within the framework of applied research on sewerage, led by Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT).

WEeeT-CAM, an in-house start-up launched under Ricoh's new business creation initiative ‘TRIBUS’, participated in the study to examine the development of 3D-printed hydroelectric power generators.

The study verified its usability at sewage treatment plant through industry-academia collaboration with Seabell Incorporated and Masashi YAMABE – Masahiro SETO Laboratory at Department of Mechanical Engineering, Kanazawa Institute of Technology.

The study generated several kW of electricity using equipment with blades 25% lighter and main bodies 15% lighter than conventional metal hydroelectric power generation devices.

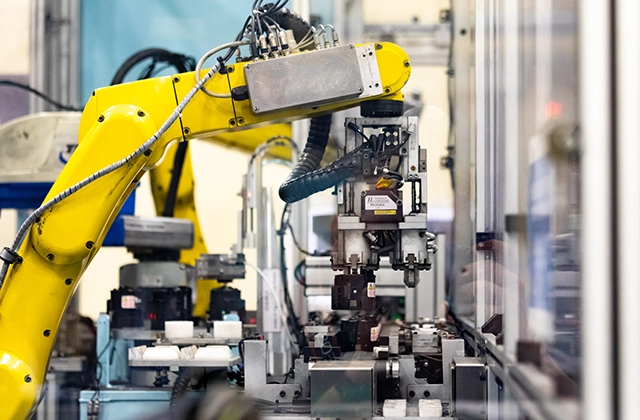

Ricoh UK Products Ltd (RPL) was proud to announce that it supported the project start-up phase in 2020. The Ricoh 3D team was responsible for generating 3D printed parts in PA12 and Polypropylene, which were utilised by RCL’s R&D department as part of prototyping and development activities.

RPL also announced that in November 2022, Ricoh UK Products Ltd Stirling (RPLS) contributed to the project. RCL’s Research & Development (R&D) Project Manager, Research Principal, Mr Akira Saito visited Stirling for ‘demo testing’, utilising the local burn (stream) to test water flow under various specs and restrictions.

Following initial support from RPL, Ricoh Company Limited leveraged 3D printer technology to create a micro-hydroelectric generator incorporating 3D printed blades made of biomass-derived materials. Compared to a water turbine made from commonly used 3D printer materials, the turbine was more than twice as strong as a metal turbine. It was found that the strength was maintained even after being placed underwater for a long period of time and could be used for large-scale hydroelectric power generation.

The study also significantly shortened the production period from roughly one month to three days. The waterwheel part was made of resin for improved underwater durability.

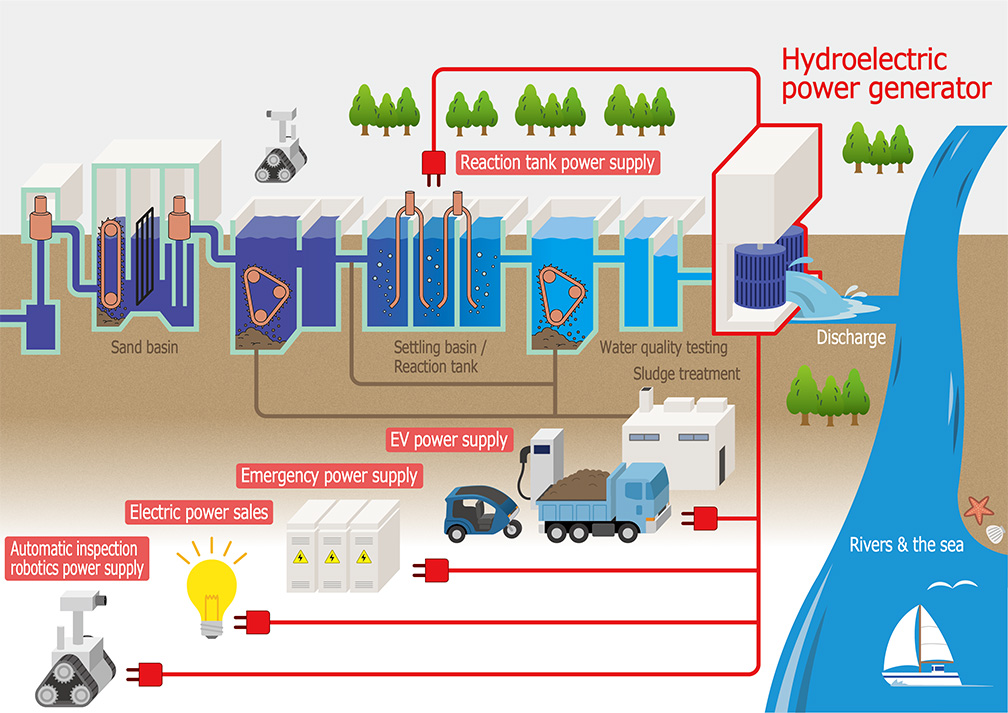

In the future, the electricity generated by these devices is expected to be used as emergency power supply at the disaster prevention centres within sewage treatment plants, and battery systems that provide power for mobility, as well as in crawler-type automatic inspection robots.

In addition to installing micro-hydroelectric power generators at sewage treatment plants in Japan, Ricoh will continue to study the possibility of introducing the technology in Europe, the United States, and emerging economies – with Ricoh 3D continuing to support.

Oyama commented: “Ricoh will continue to solve social issues through its business activities and provide value that is useful to society.”

Background

Garbage, sand, and dirt are allowed to settle out through the sewage treatment process. The sewage is then pumped into a tank to break down impurities using microorganisms. Keeping these microorganisms active requires a constant supply of oxygen into the water, which consumes approximately 75kWh*, a considerable amount of electric power equivalent to roughly 110 billion yen in electricity bills annually. So, there is a pressing need to reduce power consumption to conserve energy and lower costs.

Some sewage treatment plants currently make use of micro-hydroelectric power generators, but conventional equipment poses the following issues: (1) low turbine efficiency and low output, (2) high purchase and installation costs of hydroelectric power generation equipment, (3) significant equipment heavily burdens the on-site personnel, and (4) the current micro-hydroelectric power generation equipment is challenging to use in environments that exacerbate rusting.

In response to these issues, MLIT is currently engaged in technology demonstrations and applied research to realise green innovation in sewerage systems. In March 2022, a study commenced in the field of applied research for sewerage systems based on a proposal led by Ricoh.

* Source: Subcommittee Report on Studies for Contributing to a Decarbonized Society, Sewage Policy Research Committee, released by Japan's MLIT.

Details of the study

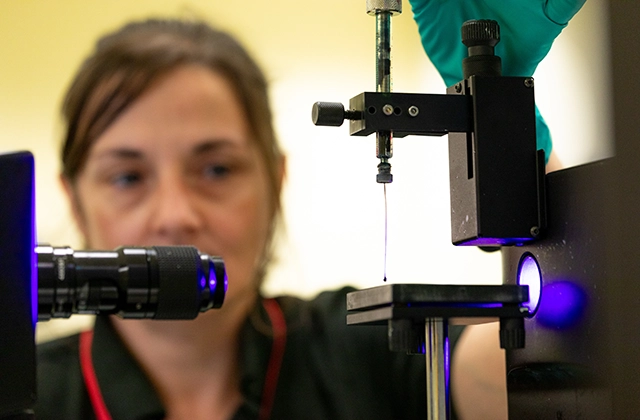

The water turbine shape was designed in collaboration with Seabell Incorporated, a manufacturer specialising in low-head micro-hydroelectric power generators, and the Kanazawa Institute of Technology. Demonstration experiments were conducted at a sewage treatment plant in Shizuoka Prefecture, Japan.

The micro-hydroelectric power generator used features two generators mounted on a single unit, allowing efficient power generation. Additionally, as an open-type device, the waterwheel can be placed directly in the existing waterway, eliminating the need to construct a new bypass waterway for hydroelectric power generation and reducing construction cost.

Ricoh's 3D printer technology was used to create a micro-hydroelectric generator incorporating 3D printed blades made of biomass-derived* materials. Compared to a water turbine made from commonly used 3D printer materials, the turbine is more than twice as strong** as a metal turbine. It was found that the strength was maintained even after being placed underwater for a long period of time and could be used for large-scale hydroelectric power generation.

* Renewable organic resources derived from living organisms; does not include fossil resources.

** A maximum bending fracture stress of 133 N/mm² using the R3D New method developed by Ricoh, compared to the 60 N/mm² provided by the resin characteristics of conventional materials.

Ricoh completes study on micro-hydroelectric power generation in utilizing 3D printers