We're sorry, but the page you are looking for can not be found.

You might try searching our website or starting at our homepage.

-

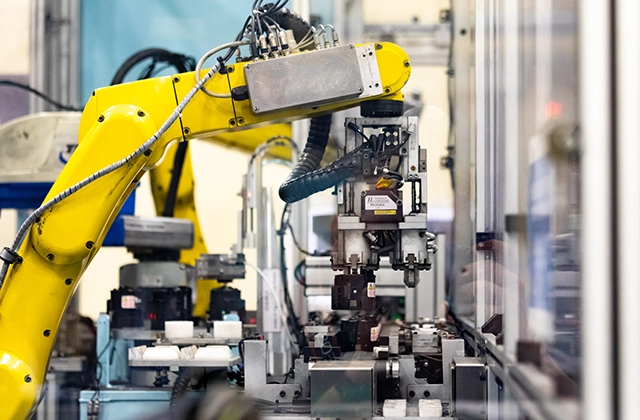

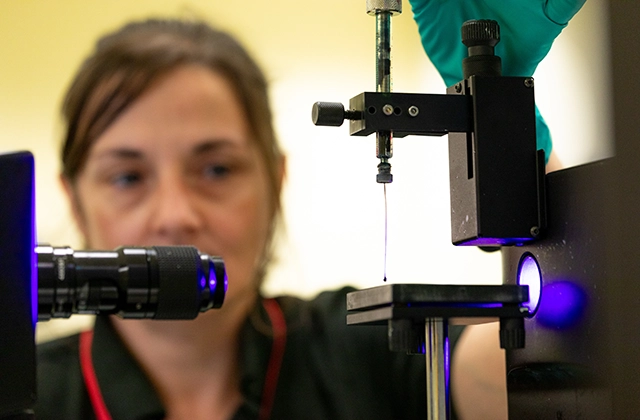

Business Solutions

Ricoh offers a range of professional solutions to help your organisation excel in a competitive marketplace.

-

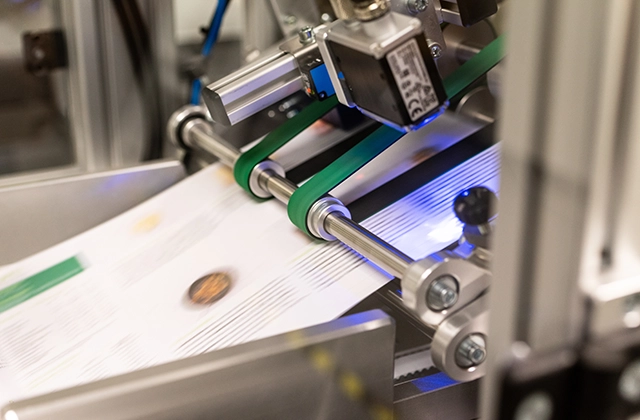

Products

Our range of industry-leading hardware and software products has been designed to enhance every environment.

-

Get in touch

Request more information about our products and services, make a support request, discover where to buy a Ricoh product, or speak to our press office.

-

Support

Find information, download software, drivers and manuals, submit meter readings, register your products.